The HTML document (below) was scanned/transcribed by the author's nephew (W. G. T. Walker), from a reprint publication, published by the Institute of the Aeronautical Sciences, 2 East 64th Street, New York 21, NY. The original typeface and layout have not been preserved; in particular footnotes have been replaced by [in-line text], and in-line figures have been moved to separate sections.

Other publications by the author Dr. Percy Brooksbank Walker include:

Other publications by the author Dr. Percy Brooksbank Walker include:

Early Aviation at Farnborough (Vol 1), Balloons, Kites and Airships. Percy B. Walker. Published by McDonald and Co., London 1971. SBN 0 356 03520 4.

Early Aviation at Farnborough (Vol 2), The First Aeroplanes. Percy B. Walker. Published by McDonald and Co., London 1974. SBN 0 356 04696 6.

Percy B. Walker (1903 – 1979): Biography

Percy Walker spent the whole of his working life on aircraft and aircraft design, most of it at the Royal Aircraft Establishment. A Fellow of the Royal Aeronautical Society and a Chartered Engineer, he went from Cambridge to join the design team of the airship R101 at Cardington, was awarded a Ph.D for his work on the Wagner theory of fluid motion, and spent five years in the aircraft industry. He joined the Airworthiness Department at Farnborough before World War II, spent the war years at the Ministry of Aircraft Production, and returned after the war to the RAE as head of the Aircraft Structured Department. In 1958 he was awarded the silver medal of the Royal Aeronautical Society and in 1964 the Distinguished Service Award of the Flight Safety Foundation, notably for his part in investigating the Comet jet airliner crashes and his experiments into cabin-pressure fatigue. [Section (3.4) of the paper below, presented in 1951, summarises the approach used in the 1954 Comet investigations.] On his retirement he held the post of Special Consultant to the Director of the RAE.

See also the Science Museum Group's profile of P.B. Walker, linked to its archive collection of The P.B. Walker papers.

JOURNAL OF THE AERONAUTICAL SCIENCES

VOLUME 19 NUMBER 5, MARCH 1952

THE EXPERIMENTAL APPROACH TO AIRCRAFT STRUCTURAL RESEARCH*, THE FIFTEENTH WRIGHT BROTHERS LECTURE

P. B. WALKER, M.A., PH.D., F.R.Ae.S**

Royal Aircraft Establishment

Presented before the Institute of the Aeronautical Sciences in the U.S. Chamber of Commerce Auditorium, Washington, D.C., December 17, 1951.

* I wish to thank the Chief Scientist of the British Ministry of Supply and the Director of the Royal Aircraft Establishment for permission to present this paper, though the opinions expressed are my own. I would also like to express my thanks to my colleagues at the R.A.E. who have assisted me in its preparation, and also those who have allowed me to make free use of their unpublished work.

** Head, Structures Department.

SUMMARY

Research in aircraft structures is constantly bringing forward new problems of a fundamental character. Many of these respond to systematic experiment, and the paper presents the experimental approach in terms of recent work done in Great Britain and particularly at the Royal Aircraft Establishment.

One aspect of research considered is the testing of small specimens made of Xylonite. Another is the strength testing of actual aircraft, which opens up several fields of research activity for discussion. Design studies of new testing equipment for large aircraft and for pressure cabins are also described. Consideration is given to the measurement of external forces in flight and the design of measuring instruments, including a description of the new counting accelerometer recently developed by the R.A.E. Finally, structural fatigue is discussed as being one of the most difficult subjects with which the structural specialist has yet had to deal.

INTRODUCTION

Aircraft structural research now covers a wide field [Ref. 1]. For the purpose of this paper it is proposed to interpret it in the somewhat restricted sense, which excludes the dynamic structural work such as transient loading, vibration, and aeroelasticity. By selecting for discussion the experimental approach, moreover, as distinct from what might be referred to as the theoretical approach, the field is still further restricted.

The words "experimental" and "theoretical," however, as used in this connection, may be somewhat misleading. The experimental approach is more scientific than some suppose, and it does not lead anywhere unless it is closely related to theory. Conversely, much of what is termed "theory of structures" is really a particular branch of applied mathematics, with basic theoretical concepts already established. In some respects, therefore, it would be more appropriate to contrast the physicist's and the mathematician's approaches rather than the experimental and the theoretical.

The experimental approach to structural research, therefore, is here regarded as essentially the physicist's approach. The experimental work described is aimed primarily at the fundamentals of aircraft structural engineering. Ad hoc tests and experiments that contribute to the development of particular aircraft types are not under consideration unless they have a general significance or need to be studied from the standpoint of method and technique generally.

The particular subjects chosen for discussion are presented mainly as a study in experimental method. At the same time, the opportunity is taken to describe recent work done in Great Britain and particularly at the Royal Aircraft Establishment (RAE). It is hoped that some of the information will appear fresh to those who receive it; where this is not so, it is still hoped that there will be some interest in seeing familiar problems treated from a different point of view.

(1) THE EXPERIMENTAL STUDY OF STRUCTURAL PRINCIPLES BY MEANS OF SMALL SPECIMENS

(1.1) Introductory

To the aircraft structural engineer there is much satisfaction to be gained from small-scale experimental work done in a laboratory. This arises partly from economic considerations, but there is no doubt that the main benefits arise from the ease and speed with which small-scale work can be accomplished. New ideas can be quickly tried out experimentally, in contrast to the long delays that inevitably occur in full-scale structural work.

In the technique now to be described, small and simple structural models are made in "Xylonite" and tested under applied load to determine the distribution of stress and strain. The work is aimed mainly at the study of structural principles and is not to be confused with attempts to produce exact scale-models.

(1.2) Origin of the Method

For some years, various research workers have been experimenting in the use of small-scale models for investigating the properties of full-scale aircraft structures. Their objective was to produce in easily-workable material an exact reproduction of a structure that could conveniently be tested in a laboratory. The proprietary material "Xylonite" has been much used for the construction of such models, and there are now a number of skilled craftsmen in Great Britain who can work quickly in this material to exacting specifications.

The value of direct scale-model work, however, is now much in doubt. It is difficult, if not impossible, to produce a structurally equivalent model on a small scale and in quite different material. This work on scale models, however, has had one important result: it has inspired what is virtually a new method of experimental structural research and provided for it a ready-made technique.

In this new method, attention is concentrated on reproducing a particular structural phenomenon without detailed representation of the original structure on which it occurs. A small model is made in xylonite as before, but from the engineering standpoint it is an extremely simplified version of the original. The dimensions and stiffness properties of the simplified members, however, are carefully chosen so that the behavior of the original structure, in respect of the particular phenomenon under review, can be deduced with reasonable accuracy from the model experiments. The technique for making and testing the simplified models is very similar to that used in true scale-model work.

These tests of structural principle have only been in use at R.A.E. for a short time, but they have already proved their value. Furthermore, progress has been unhampered by minor difficulties of technique, owing to the experience already obtained in direct scale-model work. Xylonite has the advantage that deflections are comparatively large and cannot only be measured but can also be observed visually. The transparency of the Xylonite is a further advantage, since it enables the behavior of the inner parts to be observed. Facility for direct observation is useful when a phenomenon needs to be understood in a broad way before detailed investigation begins. There is, however, full scope for accurate quantitative work with dial gages and electrical-resistance strain-gages.

The method has two distinct applications. Firstly, it can be used for investigation of a particular phenomenon occurring on a specific aircraft structure. In this connection it is a valuable ancillary aid in the routine testing of large structures. Secondly, it can be used for exploring general trends in design, and has thus a place in the structural research necessary to cope with new aerodynamic forms such as sweptback and delta wings. It is now proposed to consider examples in each of these two general categories.

(1.3) Specific Application

The best examples of direct application of the method to particular structures arise in the course of routine strength testing. Most aircraft nowadays are tested before final acceptance, and from time to time a structure behaves in a way that is entirely unexpected. Premature failure may sometimes be explained by a mistake in calculation or by defective material, but frequently the explanation goes much deeper. The underlying theory or the basic assumptions may be at fault, and it is in such cases that a small-scale test of structural principle is called for.

A good example occurred only recently. Premature failure occurred on the wing of a wing-engined aircraft in the neighborhood of the attachments to one of the engines. The weakness could not be explained in any simple way, and some more fundamental explanation was sought. The most obviously unusual features were (a) the positions of the engines, which were much further forward than on any previous aircraft tested and (b) the lightness of the ribs compared with those of previous aircraft.

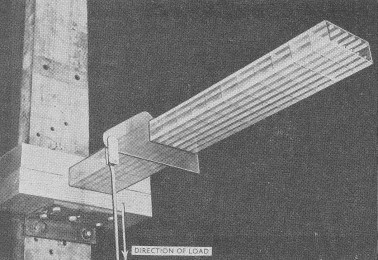

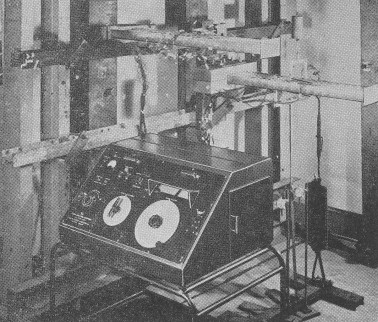

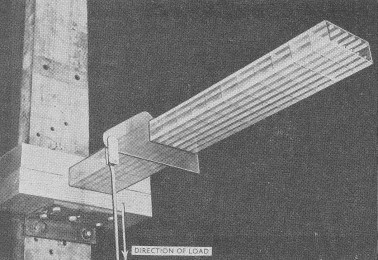

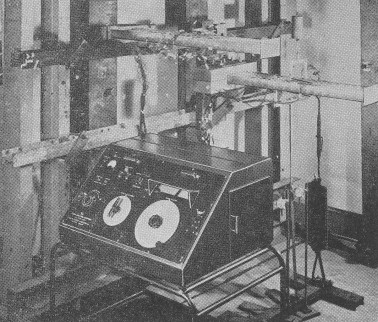

A Xylonite test-specimen was made reproducing a simplified version of the main structure of the original wing and engine mounting as shown in Fig. 1. The specimen was essentially a long rectangular box reinforced by ribs and stringers and carrying a projection representing the engine. The resultant engine load is indicated by an arrow in the picture. The structure was made as simple as possible, but dimensions were chosen to ensure that the phenomenon could be investigated quantitatively (to a reasonable degree of accuracy) as well as qualitatively. Deflection gages and strain gages were installed in the usual way (Fig.2), an identical second model being used for the dummy strain gages required for temperature compensation.

In the early stages of the experiment, it became clear that something unexpected was happening, and the investigators were not left long in doubt as to the explanation of the premature failure of the actual wing. In the original calculation of the stresses, the customary allowance had been made both for the engine load and also for its concentrated application. The theory used, however, did not go far enough. It had been assumed for the purpose of analysis that the ribs were infinitely stiff — a legitimate working assumption for most structural problems. In this particular case however, the actual flexibility, not only of the rib to which the engine was attached but also of the ribs outboard, was found to cause additional stress concentrations in the wing which had clearly given rise to the premature failure.

The error was shown by these experiments to be approximately 15 per cent which almost exactly accounted for the discrepancy found in the test of the original structure. Thereafter, remedial action was straightforward. The front spar of the wing was strengthened locally to the extent indicated by the experiments.

It is of interest to remark that this phenomenon had been noticed for the first time partly because the engine was further forward than hitherto and partly because the designers had been extremely careful in reducing structure weight to the minimum — working to what had then been the accepted theory for wing design. Now that the explanation of the discrepancy has been obtained, a recurrence of the trouble on future aircraft is unlikely.

In the light of this experience it is unnecessary to stress the value of this method of investigation, but there is one other point to emphasize — the Xylonite models were made and the essential preliminary test completed in about 3 weeks.

(1.4) The Study of General Trends

The application of the method to the study of general trends in design presents a much less clearly defined

field of activity. It is necessary to bear in mind that the method has not been in use very long and that its full possibilities cannot yet have been exploited. There are on record, however, a few general investigations on sweptback and delta wings which are of interest.

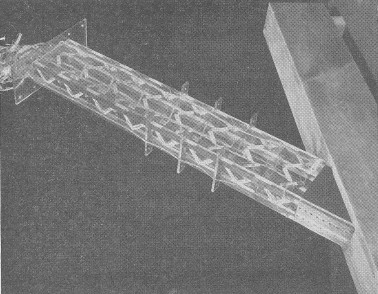

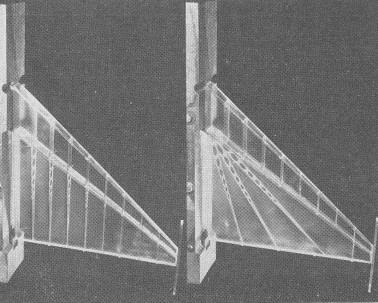

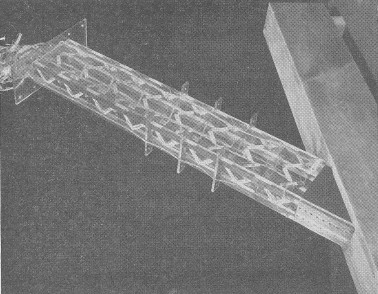

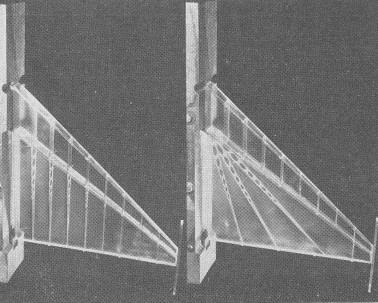

The first example treats the sweptback wing as a "conventional" straight wing merely inclined backwards (Fig. 3). There is thus introduced the additional wedge of wing structure indicated on the photograph. Simple xylonite models of both "straight" and sweptback versions were tested and the results compared. The experiment showed that for the sweptback wing — working inwards toward the root — there is a shedding of load (shear and bending moment) from the front spar, with a corresponding increase in the rear spar. In other words, the loads tend to take the shortest path to the fuselage. The extent of load transfer depends on relative sizes of the members and angle of sweepback, but it can be determined in any specific case with a fair degree of accuracy. For the average type of sweptback wing with, say, 40° sweepback, the increased load in the rear spar at the root is about 15 per cent.

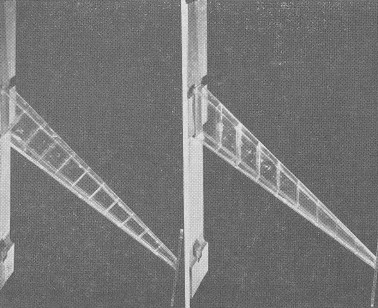

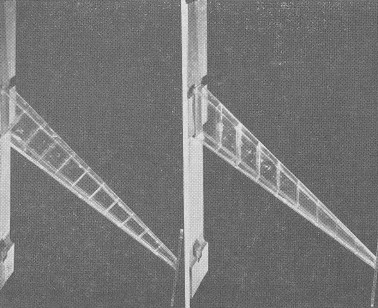

The second example concerns the direction of the main ribs. As a structure analogous to a "straight" wing structure the ribs should lie approximately at right angles to the spars as shown on the left of Fig. 4. Considerations of aerodynamic efficiency, however, generally prescribe that the ribs should lie in the direction of flight, as shown on the right in Fig. 4. The aerodynamic value of such ribs is still arguable in some cases, but it is clearly necessary that their associated structural penalties be properly assessed. To deal with this problem a pair of boxes of simple construction, reproducing the main characteristics of the structural part of a swept wing, was made as illustrated, with ribs in the two directions, respectively. The tests showed that the "structural" ribs (perpendicular to the spars) are superior to the "aerodynamic" ribs (parallel to the line of flight), both for stiffness and strength. The difference, however, is not great, and, in general, the increase of strength and stiffness to be obtained by inclining the ribs to the line of flight is of the order of 5 per cent.

The third example concerns the trailing portion of the delta wing, aft of the main structure. On the left of Fig. 5 the trailing ribs are shown parallel to the direction of flight. The alternative is to support the trailing portion of the wing by members directly attached to the root as shown on the right of Fig. 5, where the ribs are spread out fanwise from the root of the rear spar. To deal with this problem, simple specimens with the two types of trailing ribs were made as before and tested. It was found that for the same structure weight the fanwise ribs are slightly superior structurally to the fore- and aft-ribs, both with regard to strength and stiffness.

These three examples of preliminary work with Xylonite models indicate that there is considerable scope for assisting the aircraft designer when he has to decide the general layout of his design. They also indicate that it may often be worth while making and testing a simple Xylonite model of a structure whenever it is proposed to depart appreciably from conventional practice.

(2) STRENGTH TESTING OF COMPLETE AIRCRAFT

(2.1) Introductory

From the testing of small "models" we now pass on to consideration of the very different task of strength testing real structures. Most new designs of aircraft nowadays are strength-tested in more-or-less complete form before being released for service. [Actually, it is common practice with large aircraft to test wing and fuselage systems separately. It is then usual to have one system complete and accompanied by sufficient of the other for accurate load representation, and there is no departure in principle from the testing of the complete aircraft.] The immediate purpose of each test is to check whether the aircraft meets the standard of strength previously laid down as being necessary for safety and operational usefulness. Should any structure fail prematurely, however, there is then the further purpose of determining the nature and situation of the weakness so that it can be rectified.

The work as a whole opens up several fields for research activity, in spite of its superficially routine character, and it is proposed to consider three of the more general aspects of routine strength testing which have received particular attention recently in Great Britain.

(2.2) Safety and Structural Efficiency

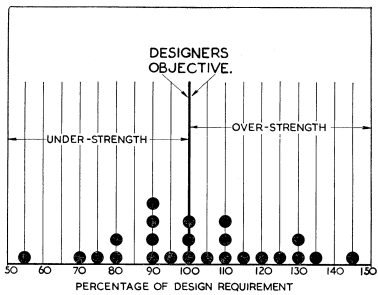

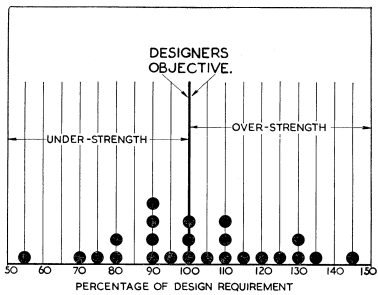

From time to time it is necessary to consider whether the effort being expended on major strength testing is justified from the standpoint of safety and efficiency of the individual aircraft types concerned, and whether the work as a whole is being directed to best advantage. The best indication of the need for major strength tests is to be obtained from a study of past records. A review of results obtained in the past 10 years or so was recently made in Great Britain [Ref. 2]. Among information of various kinds collected, the most comprehensive concerned 24 wing systems, and it is to these that the following analysis refers.

Initial results for the aircraft are indicated diagrammatically in Fig. 6. Each circle in the diagram represents a particular aircraft, and the strength attained on test is plotted as a percentage of the design requirement. Of the 24 wing systems, ten are seen to be on the wrong side of the 100 per cent line. In other words more than two-fifths of the aircraft as delivered failed to meet the standard of strength their designers had set themselves, while roughly one-fifth were completely unacceptable on safety grounds. This is regarded as clear proof that strength testing of all basically new designs is necessary, and that neither structural theory nor design skill can be relied upon entirely without testing as a final check.

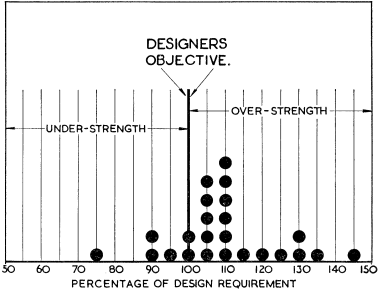

The outlook brightens considerably, however, when events following these initial failures are investigated. Of the ten understrength aircraft, nine were strengthened locally in the light of information yielded by the initial test, and the test on each was then repeated. It is significant that in the great majority of cases the alterations were minor and the corresponding increase of structure weight almost negligible. This process of modification and retesting, moreover, was carried out once again in two cases where results attained in the second test were still unsatisfactory. It was also applied to a few designs that, though meeting the design requirement, showed good prospects of useful extra strength being attained at small cost in structure weight.

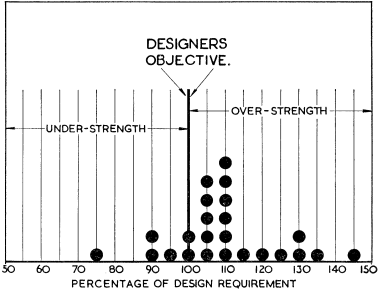

Fig. 7 shows the result when one alteration is allowed if required, or two alterations in rare cases. It is seen that there are now only four aircraft (or one-eighth of the total) on the wrong side of the 100 per cent line and that only one is less than 90 per cent. Even this result requires some qualification: it was not always considered necessary to retest aircraft achieving 90 per cent or more, and two were retested only once while one was not retested at all. It is of interest to note, moreover, that even the one aircraft that did not respond to two minor alterations had fundamentally a sound structure; and, although something more than minor alteration was necessary, it was brought up to standard without much difficulty and at a surprisingly small increase in structure weight.

These results attained after minor alterations are giving support to a philosophy of design which many have followed in the past intuitively. It is maintained that the most efficient designs — that is, designs with the lightest structure for a given strength — are most likely to be obtained when the designer deliberately takes a few chances and relies on strength tests to detect any weakness. It can be argued that, in order to have prevented any one of these premature failures, it would have been necessary to have disposed extra structure weight fairly liberally over much of the structure and not merely in one place, since the precise form of failure was unpredictable. The case for proceeding on these lines, moreover, is further strengthened by the fact that many of the structures that failed prematurely in the first test were ultimately among the most efficient of them all.

This principle can, of course, be carried too far. There is always a possibility that too much confidence might produce a structure that is altogether too weak and beyond simple rectification. More likely, however, is that serious delay may be occasioned through numerous petty modifications and retests while an aircraft is waiting for the results before it can be allowed to fly. The solution to the problem thus presented may therefore be some kind of compromise, and there is a good case for supposing that something close to the best compromise is already being attained in current practice.

Before discussion on this subject can be closed, it is necessary to consider to what extent such deduction from past experience can legitimately be applied to the future, and generally to temper statistical analysis with engineering judgment. The number of aircraft showing excessive strength gave rise to some concern until it was found that they were mostly early types created when the need for weight economy was not realized so acutely as it is now. There are good grounds to believe, in fact, that future aircraft are most unlikely to be made excessively strong. On the contrary, there are indications that the proportion of premature failures on first test may well increase and even that the trend in this direction has already begun. This is consistent with the principle of modification and retest already mentioned and gives grounds for satisfaction rather than alarm, particularly since there is no evidence of the principle being carried to excess.

(2.3) Contribution to Fundamental Knowledge

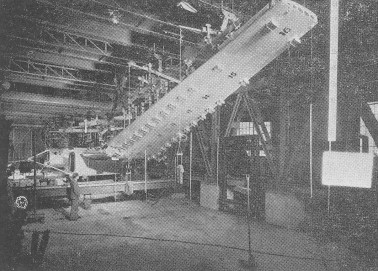

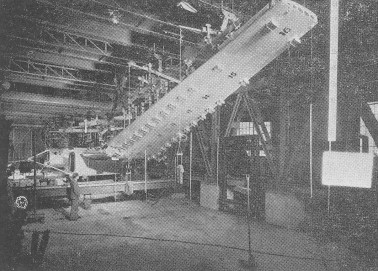

The satisfactory clearance of specific aircraft types must always remain the first objective in major strength testing carried out as a routine. Nevertheless, the tests are not being used to full advantage unless they are made to contribute to the store of general structural knowledge and to improve the breed of aircraft generally. Major strength tests are costly in time, money, and effort; and for this reason they can rarely be undertaken for research purposes alone. Every possibility must therefore be taken to obtain from the ad hoc tests as much fundamental and general information as possible. In the course of years a great variety of failures occur, since each test is normally taken to destruction (Fig. 8) and many new and unsuspected modes of structural behavior are revealed from time to time.

At the R.A.E. there now exists a small team of specialists charged solely with the task of extracting fundamental lessons from these major strength tests. Its members are not directly concerned with the ad hoc purposes of the test, though they naturally collaborate closely with those who are. In event of premature failure, moreover, they often help considerably in the diagnosis of the cause. Their main instrumental aid is the electrical-resistance strain gage, and strain gages are distributed liberally over parts of the structure deemed to be especially vulnerable or of special scientific interest.

It is not possible, of course, to narrate here all the conclusions that have been drawn from such investigations. Often the work does not appear as an account of a particular test but as a study of a specific structural problem supported by further theoretical work. One general conclusion, however, appears worth mentioning. This is that the most common single cause of premature failure is a "stress diffusion" problem. In other words, while ample material may be present to carry the internal load in a particular region, some part of the structure carries a greater share than the designer intended or expected.

(2.4) Technique of Force Control

Another field of study related to major strength testing concerns the testing technique, which needs always to be kept up to date and in line with modern requirements. The most important branch of testing technique is the control of the applied forces. This presents a problem much more serious than is generally realized and for which it is probably true to say that no really satisfactory solution has yet been found.

A few years ago the writer undertook an investigation into the principles of force control [Ref. 3]. The conclusion was reached that the main difficulties arise from the interaction of the various strainers, as the force-controlling units are generally termed. While the number of strainers is reduced, by means of the well-known lever system (Fig. 9), to a small fraction of the number of forces applied to the structure, there are still several in a test of any magnitude.

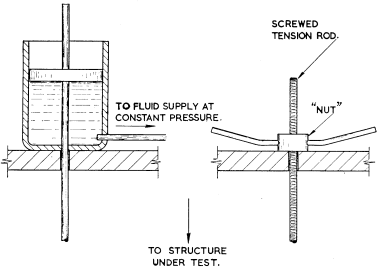

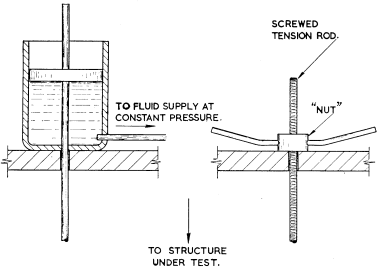

The investigation also led to the further conclusion that there are two basic types of strainer according to whether force is controlled directly or indirectly through displacement. The direct force-controlling strainer must be mechanically reversible, so that it is free to move to and fro without change in the force, as the structure distorts under the action of the other strainers in the system. Such a strainer may be pictured as a frictionless hydraulic ram supplied with fluid at a constant predetermined pressure (Fig. 10, left). Conversely, the. displacement-controlling strainer must clearly be irreversible and is best represented by a screw jack (Fig. 10, right).

Unfortunately, neither basic type of strainer is satisfactory in any simple form. The reversible strainer may give rise to dynamic effects and to instability of the whole system, [Ref. 4] but its chief disadvantage is the extra damage it may do to the structure after initial primary failure. The irreversible (screw-jack) type of strainer has none of these disadvantages, but it does not give complete control of the force system, since the relation between forces and displacements depends on the characteristics of the structure and is never known precisely.

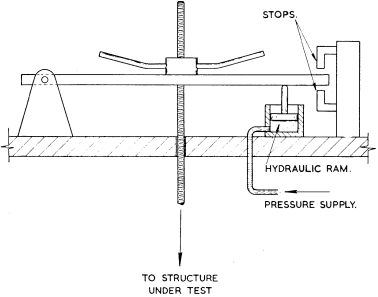

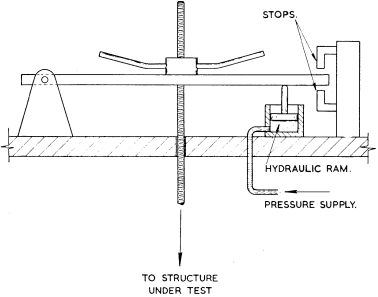

All practical types of strainer are then seen as combinations of these two basic types produced with a view to obtaining, so far as possible, the advantages of both and rejecting the disadvantages. The R.A.E. compound strainer (Fig. 11) is a simple illustration of this principle. An irreversible screw-jack is used but is suspended from a lever that is supported by a small hydraulic ram. The travel of this lever, however, is restricted to something small by stops. Thus the strainer is irreversible in respect of large movements and reversible in respect of small.

The leverages and ram diameters are actually arranged so that all the rams in a complete system of strainers require the same pressure for the prescribed loading ratios, and they are interconnected by pipe lines. In operation, the main straining is done by screw-jacks and a coarse adjustment of forces obtained. Final adjustment is then obtained automatically on the hydraulic system.

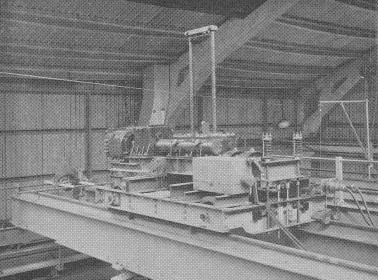

Fig. 12 shows the strainer in a practical form. There are two coupled screw-jacks, handed to eliminate torque, which are driven by electric motors. As a result of the investigation that has been made, it is proposed to develop this type rather than proceed on entirely new lines. In the existing system, control is automatic for the hydraulic part of the system, and all the screw jacks are controlled from a central control room, though each in some measure individually. Successful experiments have been made on a small scale to eliminate individual control entirely and to give a completely automatic system. The full application of this method to regular testing is an immediate aim for the future.

(3) DESIGN OF TEST FRAMES AND PRESSURE TESTING EQUIPMENT

(3.1) Introductory

The next subject for consideration is the design of the testing gear used in the major strength tests just described and especially the test-frame structure. This is an important responsibility of the aircraft structural engineer and takes him quite outside his usual field. The design of a structure that is to be used for testing another structure is decidedly heavy engineering and as unlike aircraft engineering as it could possibly be.

Interest in design of test frames at the present time is inspired by two testing requirements that are comparatively new. One is for the testing of larger aircraft generally, and the other for testing sweptback and delta types. The largest aircraft that can be tested at R.A.E. at present has a 120-ft. span and must be of the "straight-wing" type. An aircraft not coming within this capacity has to be tested as a reduced-scale version or by improvised methods.

In addition to the prospect of extending "orthodox" methods of testing, consideration has to be given to the testing of pressure cabins. This is a new development requiring the cabin to be filled with water and totally submerged in water.

(3.2) The Universal Test Frame

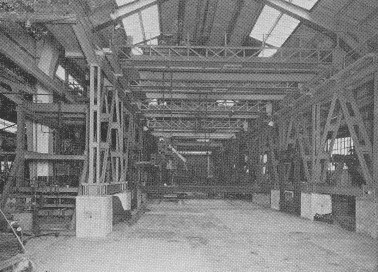

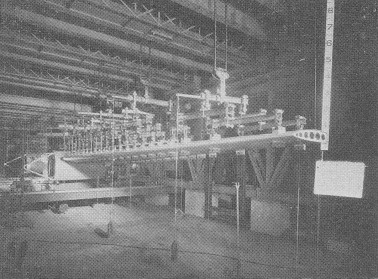

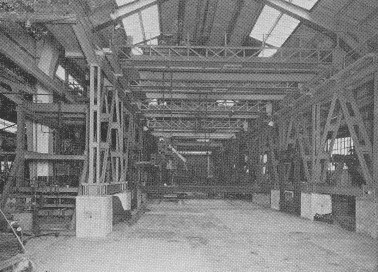

There are wide differences of opinion as to the best type of testing structure for major strength tests. Many systems call for a good deal of improvisation, the testing gear being designed to suit the particular aircraft that is to be tested. As is well known, the R.A.E. have kept consistently to the "universal test frame," which enables any aircraft within specified dimensional limits to be tested without any special constructional work apart from the lever systems. Two advantages normally conceded for the universal test frame are saving in time and labor during the process of rigging for a test and during the actual testing. These are regarded as over-riding considerations for a central experimental establishment, though not necessarily for design firms concerned with one particular aircraft during its design stages. A further advantage claimed is greater accuracy of measurement and greater precision of load control through use of equipment that is permanently installed. On the other hand, first costs are high, and it has been maintained that the system is not so flexible as others involving a greater degree of improvisation.

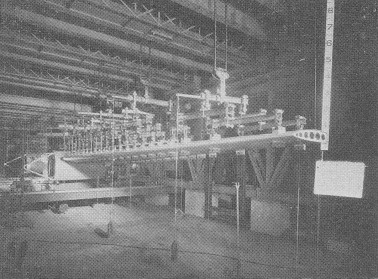

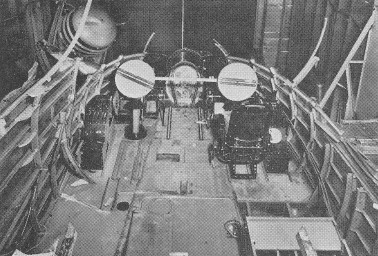

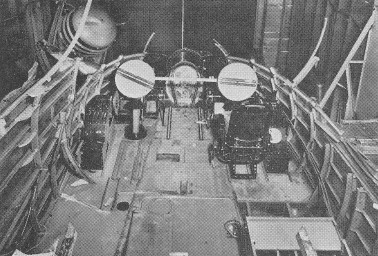

Before discussion of prospective developments in this field it is desirable to have on record a brief description of a typical universal test frame. Essentially, this is a structural box with open ends. Fig. 13 shows an end view of the "Cathedral," the largest test frame in use at R.A.E. The top of the frame consists of a series of bridges, each supported by a pair of two-wheeled carriages which can be moved along rails traversing the whole length of the test frame. These bridges also support rails on which rest the bogies that carry the upward-loading strainers. The two degrees of mobility thus obtained are utilized for initial positioning only, and, subject to minimum spacing limitations, enable the forces to be applied in any desired position.

The comparatively few downward forces are applied in three possible ways: by strainers attached to the floor structure, by levers connected to the upper strainers by tie rods, or by dead anchorages.

(3.3) Design Study of a Large Test Frame

In discussing the design of larger test frames it is proposed to consider only the requirements for wing systems, since fuselages in general are then covered automatically. The choice of an upper limit of size depends upon three considerations. There is first the probable sizes of future aircraft generally, which cannot of course, be predicted with any degree of certainty. Next there is the possibility of not testing aircraft of extreme size, since it has been argued by some that testing of such aircraft is becoming uneconomic and must be waived. Finally, there is the possibility of testing specially constructed reduced-scale versions of very large aircraft. This last method has been employed in Great Britain with apparent success and is undoubtedly better than no test at all; but it is costly in time and effort, and there is always an element of doubt as to whether the reduced-scale structure and the test itself truly represent reality.

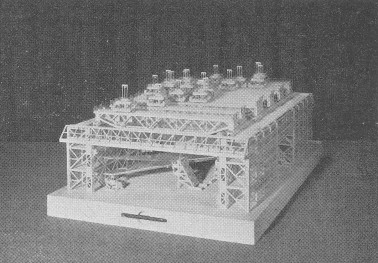

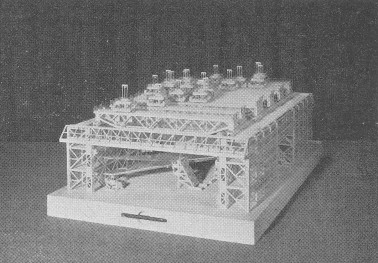

Before a proper decision on the maximum size of test frame can be reached, however, it is desirable to know what limitations, if any, are imposed by considerations of the practicability of design, construction, and operation of a universal test frame considerably larger than any in existence. Accordingly, a design study of a large test frame was recently prepared without prejudice to any later action that might be taken.

The internal dimensions of the test frame in this design study are 200 by 100 ft. Any aircraft, irrespective of shape, with a wing system not exceeding these dimensions can be tested, though it is not expected that both extreme dimensions will ever occur simultaneously. Furthermore, a straight-wing aircraft of span as great as 230 ft. can be tested provided the extreme wing tips are removed, a practice that should not lead to appreciable error. In consequence, existing aircraft like the Brabazon can be accommodated.

Fig. 14 shows a scale model of the test frame produced by this design study, with part of the building and some of the bridges removed for clarity. A model of a large sweptback wing system is also shown in Its testing position.

In the creation of this design the mobile bridges provided the greatest problem. As is well known, bridges increase in weight, depth, and width out of proportion to increase of span. The bridges shown weigh 80 tons, which is not considered excessive. In order to obtain sufficiently close loading lengthwise along the frame, however, it is necessary to have two sets of rails with the bridge carriages arranged alternately. The most critical design factor is the bearing pressure on the rails, and it is considered that the present arrangement works close, though not too close, to the practical limit.

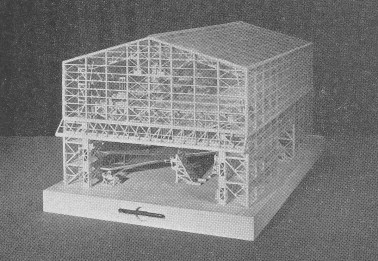

The effect of length of the test frame (corresponding to wing span) is much less serious than the effect of breadth (corresponding to gross wing chord). To cope with the tip deflections of a 200-ft. span aircraft, however, requires a clearance height of 50 ft. measured from floor to the lowest point on the bridges.

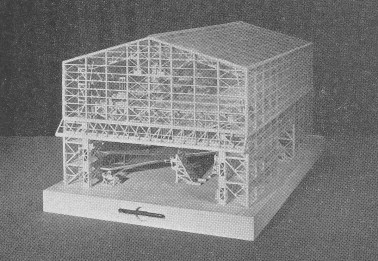

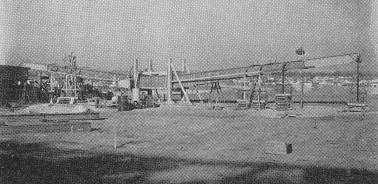

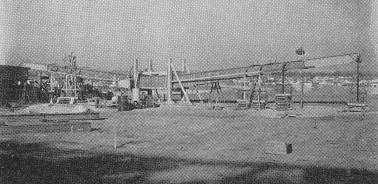

The building to house the test frame also requires serious consideration and, treated separately, costs about as much as the test frame itself. In this scheme, however, the building is constructed integrally with the frame (Fig. 15) partly for economy but also to simplify the design of the foundations. Though presenting a level surface, the floor has beneath it a stout structure incorporated in the foundations and forming an integral part of the test-frame structure. The height of the building at its highest point is about 110 ft.

(3.4) Strength Testing of Aircraft Pressure Cabins

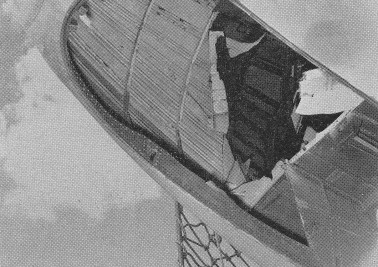

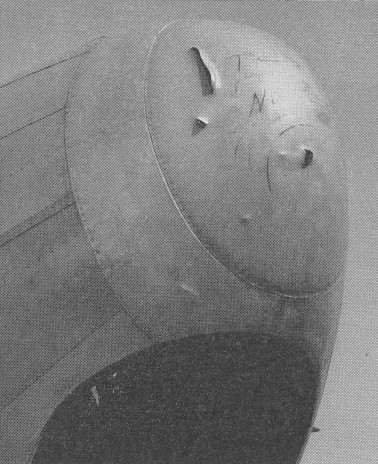

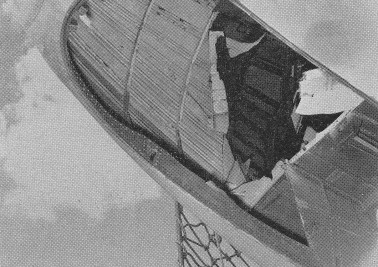

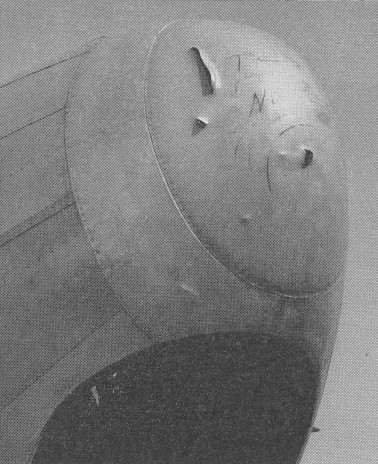

From one point of view the strength testing of pressure cabins is simple because it is merely necessary to increase the pressure until failure occurs. Unfortunately, however, when the pressure is applied in the normal way — that is, to the air within the cabin — the effect can be disastrous. In a calculation recently made by the writer, it was shown that the effect of bursting of a fair-sized pressure cabin filled with air is roughly equivalent to the bursting of a 100-lb. bomb [Ref. 5].

The testing of a pressure cabin by internal air pressure thus involves grave risk to personnel carrying out the test, and certain damage to equipment and buildings. It is, of course, conceivable that these risks might be lessened by building protective walls, but there still remains a major difficulty. The cabin structure is usually blown into small pieces so that there is little hope of diagnosing the primary weakness and no chance at all of a repair and retest.

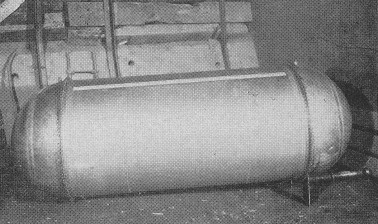

The solution lies in using water instead of air. Water inside a cabin, however, introduces a static head that cannot be ignored, and the total weight may be so great that it cannot be supported without introducing extra loads of appreciable magnitude. The whole cabin is therefore submerged in water as well as filled with water.

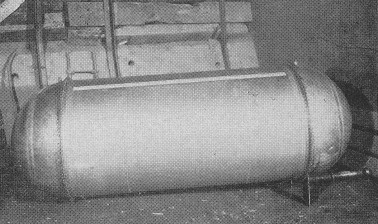

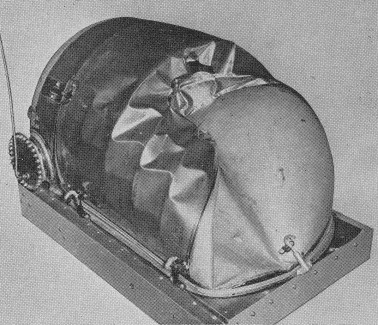

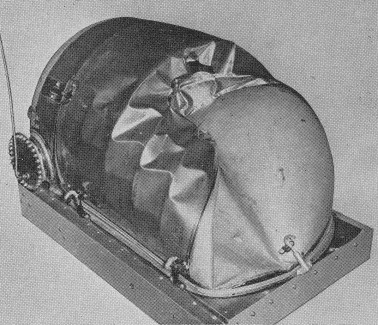

The calculations already mentioned show that the available energy stored in the compressed water is of the order of one ten-thousandth part of that stored by air under the same conditions. Furthermore, the presence of the water lessens damage still further by damping down any tendency to violent motion. In consequence, failures in a water test are usually localized even to a greater degree than in ordinary strength testing, and the diagnosis of the primary weakness is rendered easy. The difference between the effects of air and water is well illustrated by the results of some comparative experiments. Two identical cylinders were made (Fig. 16) about 9 ft. long and 3 ft. in diameter.

In an air test the first specimen was blown to pieces, as shown in Fig. 17. A corresponding test in water, however, gave results as shown in Fig. 18. In this last picture, the undamaged ends have been removed for inspection, and it is seen that the only damage is failure of the rivets along the seam.

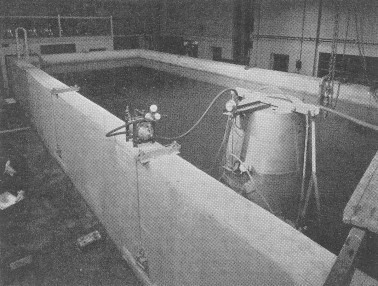

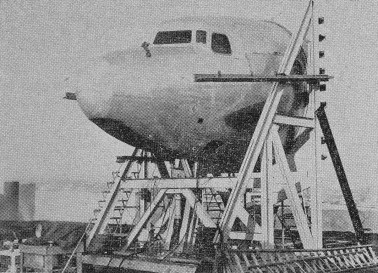

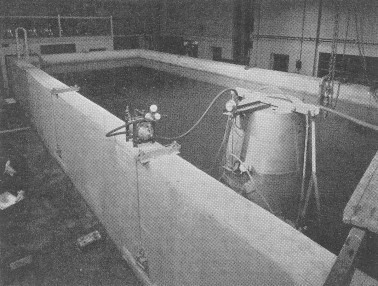

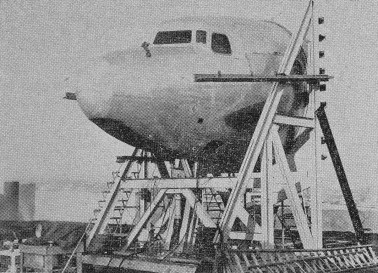

One of the main characteristics of water pressure testing is its extreme simplicity. Care has to be taken that little or no air is trapped in the cabin. Pressure is produced by a simple hand pump. Fig. 19 shows a testing tank, recently constructed at R.A.E., in the course of some preliminary experiments. The tank is 15 ft. deep, half of this being below ground level, and pressure cabins of most aircraft can be accommodated.

(3.5) Design of a Fuselage Test Frame for Combined Pressure and Structural Loading

The foregoing discussion on testing of pressure cabins relates to pure pressure tests. In the absence of anything better these serve a useful purpose, but in practice the cabin structure carries primary structure loads as well as pressure loads. A design study has therefore been made of a combined test frame on the lines already described for the normal test frame.

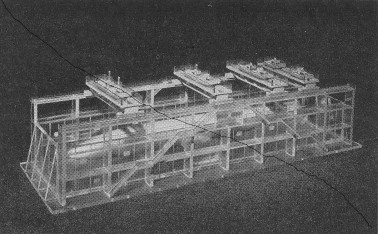

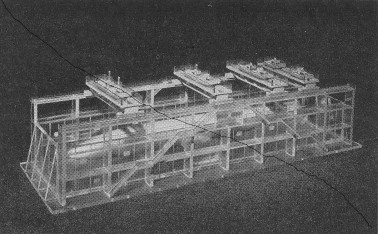

Fig. 20 is a photograph of a transparent model of the test frame produced in this design study. Essentially, it is a normal test frame, with proportions and dimensions appropriate to the testing of complete fuselages, but it is almost completely submerged in a tank of water. Only the bridges and upper strainers, a few of which are shown in the picture, stand clear of the water.

For the downward forces it is not essential to have the straining units with their electrical gear under water, though this is not necessarily considered impracticable. Where not produced by dead anchorages, the few forces normally required can be transmitted through levers and tie rods to the upper strainers.

The length of the test frame is 200 ft., its internal width is 45 ft. and the clearance height is 35 ft. The ends of the tank can be lowered to give easy access during erection of the test specimen. The test frame can also be used efficiently for testing fuselages without pressure loads and without water being present.

(4) FLIGHT ACCELERATIONS AND THE COUNTING ACCELEROMETER

(4.1) Introductory

Experimental work such as that so far described deals essentially with Internal behavior of the structure, with the external forces taken for granted. Safety and structural efficiency, however, depend as much upon the proper assessment of these external forces as upon the correct determination of the stresses and strains they produce. In consequence, the study of external and internal loading have become closely integrated and both require to be investigated by the structural specialist.

In a somewhat similar way, the responsibilities of the structural specialist have extended in another direction — to include the design of instruments of measurement. The planning of any major experimental investigation is becoming increasingly a matter of deciding what can be measured and how it can be measured. The result is that experimental structural research and instrument design are in many instances inseparable parts of the same problems*

The new counting accelerometer about to be described illustrates both these trends. On the one hand, it is intended for measurement of the accelerations occurring in flight, upon which depend the main loading conditions for the aircraft. On the other hand, it has been invented by a structural specialist [James Taylor, of the R.A.E.] as a stage in the study of gusts and their effects on an aircraft structure.

This instrument is described in some detail as having prospects of becoming widely used and also as providing a good example of the principles of instrument design for specific structural objectives.

(4.2) The Counting Principle

One of the main problems in present-day design of recording instruments is to prevent them supplying too much information. There are already many instruments that produce a quantity of data greatly exceeding what can be properly analyzed and assimilated. Whenever this risk is encountered, attempts must be made to design an instrument that has in some degree powers of discrimination, so that it will either reject secondary or unwanted information, or else segregate it from that which is essential so that it can be ignored,

The principle is illustrated in a remarkable degree by the Vg recorder of United States origin. Ostensibly, this form of accelerometer records as a continuous curve the variation of speed and acceleration. Actually, its purpose is to record only extreme values of speed and acceleration, and it does so in a most effective way. The recording point, in passing over the middle regions of speed and acceleration a great many times, virtually obliterates all record of them. The peaks of speed and acceleration, which occur infrequently, are then left prominently displayed as projections from the central mass.

The counting accelerometer bears a family resemblance to the Vg recorder. It also measures acceleration, though it does not measure speed. Its purpose is to record accelerations over the full range, however, and especially the fluctuations at lower levels which are one of the primary causes of structural failure in fatigue.

With this objective there is again the danger of producing too much information. A continuous record of acceleration would require too many man-hours to read and interpret when the instrument was in general use. In principle, the necessary simplification is achieved by simply counting the bumps as they occur in flight, though classifying them according to their severity. In practice, this process is modified slightly for convenience in instrument design. A range of values of acceleration separated by convenient intervals is first decided upon, and the accelerometer is then made to count separately the number of times each of these values are attained. Thus the records for a flight of any length are reduced to a few figures, each corresponding to a given level of acceleration.

Once the principle of counting is accepted, however a major problem is presented. Unless special precautions are taken, the accelerometer will count not only the accelerations corresponding to overall motion of the aircraft but also the accelerations caused by air-frame vibration. The overall accelerations are wanted as being a measure of the forces acting on the aircraft. The vibration accelerations have no such significance and are unwanted in this connection. If the two are counted indiscriminately, there is no possibility of later separation. Hence, the first requirement for a counting accelerometer is that it shall completely reject accelerations caused by vibration while truly recording those produced by overall motion of the aircraft. [This is also at least a desirable characteristic for any other form of accelerometer, though vital to the counting accelerometer for the reasons stated.]

(4.3) The Accelerometer Mechanism

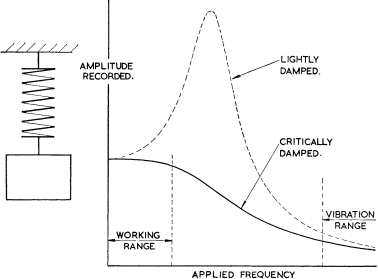

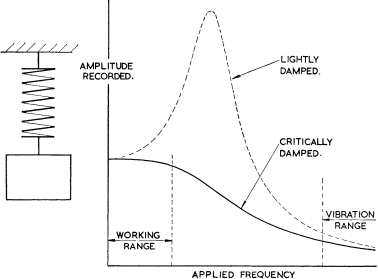

In the design of any accelerometer for recording irregular fluctuations of acceleration such as occur in flight the main problem is to render the readings of acceleration effectively independent of rate of change of acceleration. In practice, it is usual to express how nearly this independence is achieved in terms of response to a sinusoidally varying acceleration of constant amplitude, applied at various frequencies. Thus the ideal is a uniform amplitude of response for all frequencies of the applied acceleration, though this, of course, is never completely attainable. In practice a working compromise is usually obtained over a limited range by an appropriate choice of the natural frequency of the accelerometer and by heavy velocity damping.

Fig. 21 shows the simple accelerometer represented by a mass suspended on a spring. The response curve for a small degree of damping then has the shape of the curve shown dotted in the diagram, the peak corresponding to the natural frequency. With heavy damping the curve becomes much flatter, as shown by the full line. Such a flattened response curve can be used for many purposes as a basis for accelerometer design, but, as will be shown, it cannot be used for the counting accelerometer or for any accelerometer that has to reject all accelerations due to air-frame vibration.

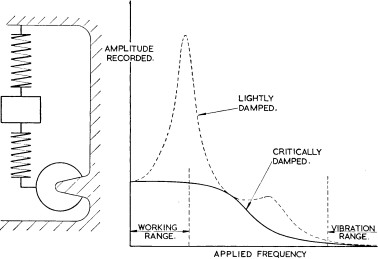

A study of the overall accelerations in flight show that they can be recorded with reasonable accuracy by any accelerometer that has a reasonably uniform response curve for a frequency range from zero up to about one and one-half times the fundamental natural frequency of the wings — usually about 4 or 5 per sec. On the other hand, the significant air-frame vibrations have frequencies exceeding about five times the wing frequency. The response requirement for the counting type of accelerometer is thus a level response curve from zero to one and one-half times the wing frequency with virtually no response at five times the wing frequency and above.

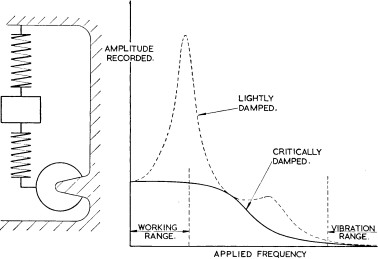

In order to meet this requirement, the simple accelerometer — a weight on a spring — is used without any damping, but the weight is coupled to what is virtually a second accelerometer (Fig. 22) having a somewhat higher natural frequency. In order that this second accelerometer respond only to movement of the mass in the first accelerometer, however, and be unaffected directly by acceleration of the aircraft, it has a rotational inertia instead of a translational one. The angle of rotation is then taken as the measure of acceleration of the aircraft.

The curves in Fig. 22 show the response curves for the compound system when the various parameters are suitably chosen. The dotted curve corresponds to a small degree of damping and has the two peaks appropriate to two degrees of freedom. When heavy damping is applied to the rotary inertia, the response curve becomes the full line, and this is the one used for the counting accelerometer. It is seen that there is a fairly uniform response in the lower frequency range, with a very low response in the higher frequency range.

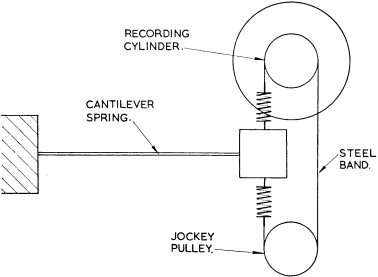

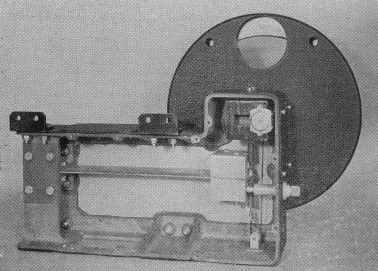

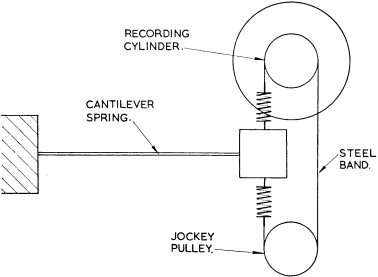

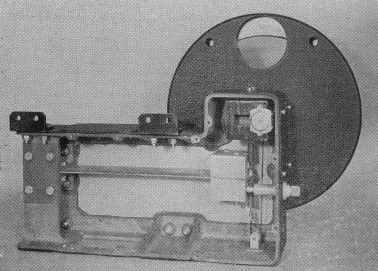

The mechanism is shown diagrammatically in Fig. 23. The translational inertia is suspended on a cantilever spring and is connected through spiral springs to a continuous band that drives the rotary inertia. A recording pointer is attached to this rotary inertia to indicate the acceleration. Fig. 24 shows the actual mechanism. Damping is by eddy currents produced in an armature (not shown), which is driven by the rotary inertia through a suitable high-speed gearing.

(4.4) The Counting Mechanism

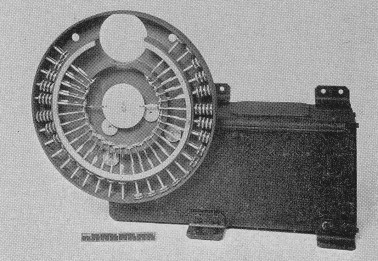

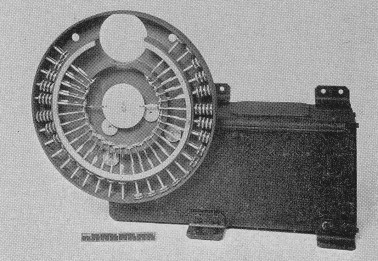

The counting is done by the simple mechanical device shown in Fig. 25. The rotational inertia in the center carries a flexible arm or pointer (the second arm should be ignored at this stage), and as this swings in either direction from the position appropriate to steady flight it passes over the series of ratchet wheels to be seen in the picture. These are spaced at intervals around the circle to correspond to intervals of, say, 0.2g acceleration and are each connected to simple counters. A ratchet and its counter are not moved when the pointer moves outward, but when it returns — as it inevitably must — the ratchet is gathered up one tooth and the counter registers one digit more.

The second pointer is introduced purely as a matter of design convenience to give suitable spacing of the ratchet wheels. Both operate in the same way, but for overall recording intervals of 0.1g one takes the odd multiples and the other takes the even. For weight economy, it will be noticed, unnecessary counter cylinders are avoided and the number of digits are reduced for high values of acceleration.

This counting mechanism incorporates two features that, though apparently trivial, have fundamental significance. In the first place, if the counters were to register strictly every time a specified value of acceleration was passed in both directions, the results could be seriously misleading. The acceleration might hover about the specified value with the counter registering an indefinite number of times. It is essential, therefore, that only changes of acceleration exceeding some minimum amount be registered. The size of the ratchet teeth are chosen to give this latitude, and the needle can oscillate anywhere through an angle not exceeding that corresponding to one tooth without a count being registered.

In the second place, there is a possibility of a miscount through the inertia of the counter. On the one hand, if the flexible pointer is moving rapidly, it may be unable to move the counter. On the other hand, the counter may be moved, and its inertia then can carry it forward to register two counts instead of one. A flexible connection is therefore interposed between each ratchet wheel and its counters. This sets a definite upper limit to the speed at which the counter can move, and ensures that it always registers a single count.

(4.5) The Counting Accelerometer in Use

The counting accelerometer has been well tried out in flights on different aircraft over many thousands of miles. It has given little trouble and so far shows every sign of being completely reliable. Already valuable information has been obtained concerning gust loadings which is being applied in the study of fatigue.

In principle, the accelerometer has one limitation, such as is to be expected when information is deliberately suppressed in order to obtain usable data. For completely random variation of acceleration information is lacking concerning the order in which the various levels of acceleration are crossed. In practice, however, this characteristic does not amount to anything serious. The normal fluctuations of acceleration on an aeroplane follow a fairly simple pattern.

For calibration and testing the accelerometer can be coupled to a continuous electrical recording system that gives the order in which the various thresholds are crossed. When a few hours preliminary flying have been done on a particular aircraft, it is possible to make a statistical analysis and to apply the results to the accelerometer counts obtained in the ordinary way.

The counting accelerometer with electrical recording has incidentally many applications in research experiments, but the electrical equipment is too heavy for routine use or for statistical work generally. The mechanical version, on the other hand, weighs about 12 lb. and is sufficiently small to be installed in aircraft engaged in routine flying.

(5) AIRCRAFT STRUCTURAL FATIGUE

(5.1) Introductory

No discussion of experimental research in aircraft structures could be regarded as complete without some mention of fatigue. Little is known about the fundamental causes of fatigue failure from the metallurgical standpoint. The structural specialist, therefore, has to rely mainly upon the experimental approach to meet the needs of the aircraft designer. Unfortunately, it is not possible to do much more than report progress at this stage in a task that is both long and difficult.

Some 3 years ago the writer reviewed the fatigue situation from the aircraft structural standpoint in a paper read before The Royal Aeronautical Society [Ref. 6]; The conclusion then reached was that much research was required before the designer would have the scientific background to which he was entitled. Since then systematic experimental work has been pursued vigorously in Great Britain, concurrently with ad hoc testing of new designs of aircraft and components.

Already much useful information has been obtained, but in the present state of knowledge the following remarks can only be regarded as a rather miscellaneous selection of tentative facts and preliminary ideas.

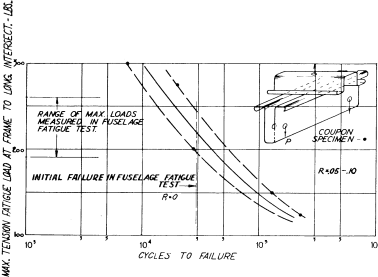

(5.2) Fatigue Testing of Wings and Tail Planes

One of the most profitable lines of fatigue investigation is the testing of wings and tail planes. These can be vibrated in their own natural modes in a way that reproduces a fair approximation to the conditions occurring in flight. At the present time, attention is being concentrated mainly on wings, since these present the more urgent design problem.

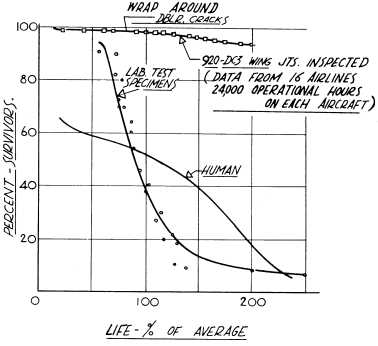

A comprehensive investigation of the fatigue properties of a wing is extremely difficult. Each test, which may take several days, gives information concerning only one particular loading cycle. For the simplest form of loading cycle, however, there are two degrees of variation corresponding to alternating and steady load, respectively. In consequence, the number of tests required is large. Furthermore, isolated tests cannot, in general, be accepted as conclusive, and more tests are required to allow for variations of nominally identical specimens. Still more tests may have to be contemplated moreover, to cover other variables such as temperature; or in order to follow up any particular line of inquiry that the original results might suggest.

The effort required for a complete survey is thus considerable and probably without parallel in any other field of structural research. The greatest difficulty of all, however, is to obtain the necessary number of specimens, which are costly and need to be as nearly identical as possible.

About 2 years ago, it was decided to test at least one type of structure exhaustively. To this end, some 50 " Meteor" tail planes were diverted from the production line, with special arrangements to prevent modifications being introduced. These tail planes were then treated as reduced-scale models of wings and were loaded accordingly as appropriate to civil and transport aircraft. In this way, not only was an adequate supply of specimens ensured, but the tests were rendered comparatively easy to conduct. The tests, of course, have no connection with the Meteor aircraft itself.

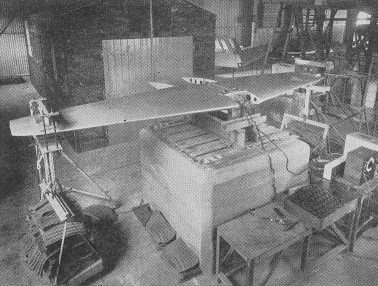

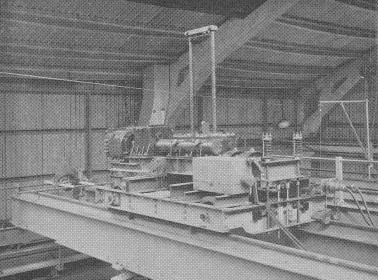

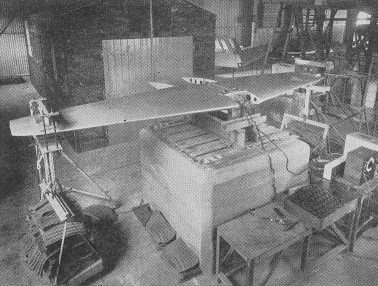

Fig. 26 shows the set-up for the fatigue tests. The "wing" system is vibrated close to its natural frequency by an out-of-balance rotating mass. Mean or steady load is applied by suspended weights carried on a low-frequency suspension system, the wings being, of course, inverted. Provision is also made for testing at low temperatures. In this case the specimen is enclosed in a heat-insulating box and cooled by air blown over solid carbon-dioxide.

So far some 20 such tests have been made. The fatigue failures experienced usually take the form of fracture of the front or rear spars near the root, though such failure is usually preceded by cracking of the adjacent skin.

Some interesting conclusions have already been drawn from these experiments. In the first place, when every care is taken over the tests, the degree of scatter through variation of specimens is much less than has generally been supposed. Secondly, the effect of mean load on this type of structure is highly significant. Application of a mean load of 25 per cent of the static ultimate reduces the fatigue strength in the million-cycle region to less than half the value for zero mean load. Finally, with regard to temperature effect, the fatigue strength increases with lowering of temperature, and in the million-cycles region the fatigue strength at -30°C, is about 10 per cent greater than at normal temperature (15°C.). Equipment is being designed, incidentally, to enable much lower temperatures to be reached, as appropriate to flight at high altitudes.

Similar tests are also being made on actual wings of large size. The number that can be tested is necessarily limited, which is one of the reasons for having a small-scale version tested exhaustively to establish general trends. At present, the technique for vibrating large wings with low natural frequencies is imperfect and still undergoing development. The alternative is a "repeated loading" system by which load indirectly applied and removed under automatic control. With this method, however, tests take much longer, and vibration methods are normally preferred.

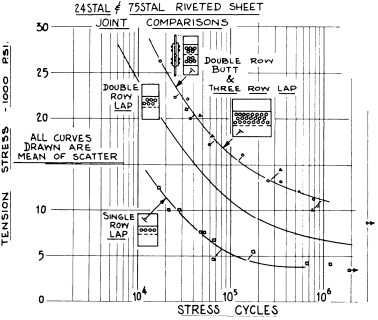

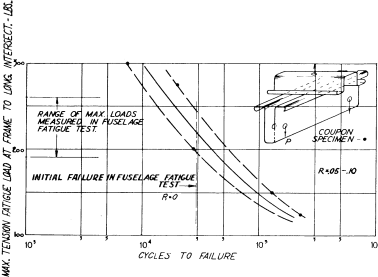

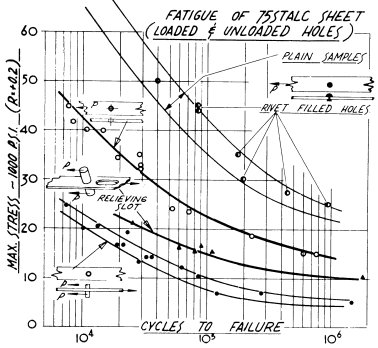

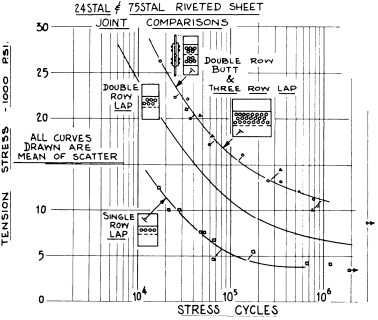

(5.3) Aircraft Joints

The major joints on an aircraft are usually the most critical parts of the structure from the fatigue standpoint. It is usual to test joints as single units before they are tested as part of a complete structure such as a wing. The tests on joints are made in one or other of the recognized tension-compression fatigue machines.

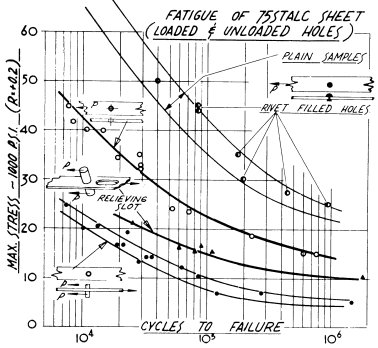

These joints are usually bolted, steel bolts being used in preference to light alloy ones because of their greater strength and more reliable fatigue properties. Experience shows that joints designed without special regard to fatigue can usually be improved upon considerably. The best designs have tapered cover plates or cleats, with bolt diameters graded to correspond.

Bolted joints illustrate in a remarkable way most of the factors adversely affecting fatigue strength. Each hole itself produces a "geometric stress concentration" in relation to the main load carried in the member. The high bearing stress on the side of the hole produces, in addition, an "applied stress concentration." Then there is the effect of unequal distribution of load between bolts placed in a line longitudinally, by which the end bolt in particular carries an undue share of load. Finally, there are present, as on any other structure component, surface imperfections that reduce fatigue strength and which can be particularly significant inside a bolt hole.

These effects are mentioned because it is by attention to them in design that most improvements are to be effected. In this connection there is particular interest in methods that have been tested experimentally with the objective of improving a joint already made without redesign or major alteration. One method is to drill a small hole just outside the critical end hole. This diverts the flow of stress away from the loaded hole and reduces the stress concentration there. Another method is to replace the end bolt of a row of steel bolts by a light alloy one, thereby reducing the load by allowing greater deflection. In cases where the holes have been drilled in the ordinary way, moreover, it has been found beneficial to ream the holes to give greater freedom from scratches, oversize bolts then being fitted. Still better results are obtainable if the insides of the holes are given a "rolled" finish, though this may be considered too costly.

Such palliative measures that can be applied retrospectively may or may not be appropriate to an ab initio design. In the design of a joint there is an economic problem as well as a technical one. Some of the ways of improving the fatigue strength are costly in production manpower and may call for skilled workmanship. It may be worthwhile in many cases, therefore, to increase the dimensions of the components of a joint and accept the weight penalty rather than to call for special treatment or skilled workmanship.

(5.4) Miscellaneous Fatigue Phenomena

In addition to the systematic study of components and complete structures, there are several miscellaneous effects worth experimental investigation. Ideas may occur to those engaged on fatigue research that can be tried out experimentally, and, even if only a small proportion yield results, the time and effort has not been wasted. It is proposed to describe three such ideas that have been pursued to some effect.

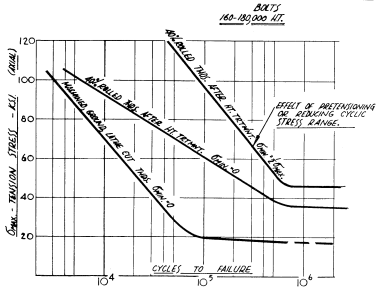

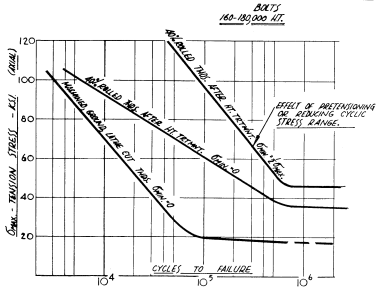

First, there is the effect of tightening steel bolts that are loaded in tension. Tests that have been made prove conclusively that a steel bolt tightened hard against a fairly robust fitting has a far greater fatigue resistance than a slack one. The tightening of the bolt introduces a steady tensile load that has to be accepted as an adverse factor, while there is a corresponding compression load in the usually much stiffer fitting. Any superimposed fluctuating load, however, is then carried by the bolt and fitting as a single member, the share of the fluctuating load carried by the bolt being small. From the fatigue standpoint the effect of reduced load fluctuation greatly outweighs the effect of the increased steady load in the bolt. Tests have shown that by proper pretensioning the fatigue life of a steel bolt may be increased to as much as 100 times the life of a lightly tightened bolt.

This phenomenon raises two important issues in aircraft design and maintenance. Firstly, there is a conflict between positive tightening and positive locking. Generally, the requirement for tight bolts should take precedence over locking, and the bolts should be unlocked and kept tight by regular inspection. Spring washers and soft packing should, of course, never be used if it is intended to take advantage of pretensioning. Secondly, there is the prospect of bolt slackening at low temperatures through the greater contraction of the light-alloy fitting. Where this is likely to have serious effects, steel bolts with a high coefficient of expansion may be used. The alternative of having light-alloy bolts is not attractive because of the better and more reliable fatigue properties of steel bolts.

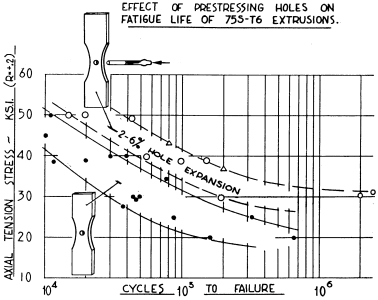

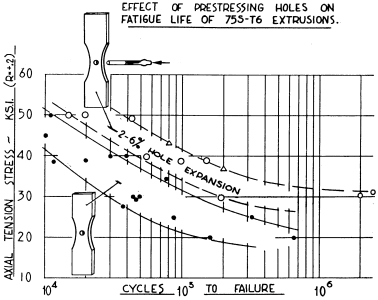

The second subject of experimental investigation is the effect of bolts or pins, that are loaded in shear, being made a tight fit in their holes. The material around each hole is then in an initial state of radical compression and peripheral tension. The effect is, broadly speaking, that the hole ceases to exist as a discontinuity so far as concerns the main stresses in the member. This benefit is again offset by the initial preloading, but when the pretensioning is done properly, a considerable increase of fatigue life can be obtained. The negative tolerance in fit, however, is critical and it is not yet known whether advantage can be taken of the principle in practice.

Finally, there is the effect of tightening bolts loaded in shear at a joint. The general effect of friction thus produced is, of course, well known but has not hitherto been regarded as very significant in light-alloy structures that have a low coefficient of friction. Experiments show, however, that tightening of shear bolts increases the fatigue life considerably. The practical significance of this has not been fully assessed. It is clearly necessary to establish what degree of reliance can be placed on the bolts being tightened and then kept tight. The phenomenon may explain the many discrepancies that have occurred in past results for fatigue life of identical joints obtained in different tests, especially where the tests have been made in different laboratories. Where somewhat involved explanations have sometimes been found, the true one may well be merely the different interpretations of the degree of tightening required.

(5.5) Prevention of Fatigue Failure

The study of fatigue failures in the past, as well as laboratory tests, emphasizes the importance of care in detail design. It is believed that the majority of serious fatigue failures that have occurred in the past could have been avoided if greater attention had been given to detail design, and particularly in the way of avoiding unnecessarily high stress concentrations. Thus, in this matter, the draughtsman takes precedence of the experimental scientist. With the great care in detail design which is now being shown, however, further improvement becomes increasingly difficult and calls for the best efforts of the structural specialist.

It is likely that for some time to come fatigue tests on major joints will be necessary for civil and transport aircraft. The sooner these can be carried out for any new design, in fact, the less is the delay likely to be caused in completing the design. It is desirable also that tests on complete wings, at least, should be made as a final check.

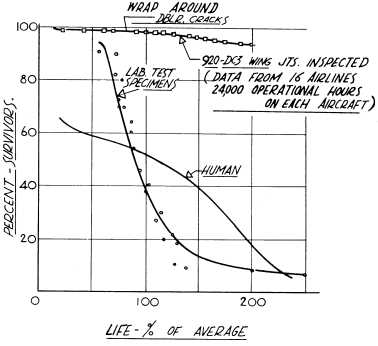

The difficulty with all these tests, however, is to decide on what loading conditions to apply and what standard to accept. It is not possible to make many tests, and the few that are made must be reasonably representative of actual operational conditions. Unfortunately, there is no satisfactory rule by which behavior under one loading cycle can be deduced from another, while a satisfactory cumulative rule by which the effect of mixed cycles can be deduced has not been found and, in a general sense, may not exist. The study of gust loadings has been helpful in the choice of a standard testing condition for design acceptance.

For aircraft in the civil or transport class an alternating load of plus or minus 7.5 per cent of the design ultimate, superimposed on the steady level flight loading, is considered to provide a good working basis. The minimum number of cycles to failure that can be accepted, however, is still debatable and in any case must depend on the working life expected from the aircraft. It is considered, however, that 2,000,000 cycles at the specified loading is not too high a figure at which to aim.

CONCLUSION

This completes an account of what is intended to be a representative selection from experimental work proceeding in the aircraft structural field, excluding dynamic work such as vibration and flutter.

It is proposed to conclude by making one comment in retrospect and to anticipate one possible criticism. Always the emphasis appears to be on the study of actual structures rather than hypothetical ones. This tendency has the advantage that effort is expended on structures that at least one professional designer regards as feasible and practical. Against this it can be argued that research should be ahead of design in all respects and applied to structures the designer has not yet thought of.

The preference for designer's designs, however, is a matter of deliberate policy, though it is not carried to extremes and tentative ventures into new types of structure are by no means excluded. The policy is only tenable with a reasonably large and vigorous aircraft industry, and such success as has been attained is largely due to the close cooperation that exists between scientists at places like the R.A.E, and designers in the British aircraft industry,

FIGURES

FIG. 1. Small-scale representation of engine-loading case.

FIG. 2. Strain-gage system for engine-loading case.

FIG. 3. Specimen representing simple sweepback.

FIG. 4. Sweptback wing — comparison of "aerodynamic" and "structural" ribs.

FIG. 5. Delta wing — comparison of fore-and-aft and radial trailing ribs.

FIG. 6. Distribution of strength of wing systems as delivered.

FIG. 7. Distribution of strength on completion of modification program.

FIG. 8. A typical test to destruction.

FIG. 9. Use of lever systems with several strainers.

FIG. 10. Diagrammatic representation of reversible and irreversible strainers.

FIG. 11. Principle of the compound strainer (R.A.E. type).

FIG. 12. Electrically-driven compound strainer (R.A.E.)

FIG. 13. End view of R.A.E. "Cathedral" test frame.

FIG. 14. Model of large test frame — 200 by 100 by 55 ft. internal dimensions.

FIG. 15. Model of large test frame with building.

FIG. 16. Model pressure cabin before test (9 by 3 ft.).

FIG. 17. Model pressure cabin after air test.

FIG. 18. Model pressure cabin (ends removed) after water test.

FIG. 19. R.A.E. strength-testing tank for pressure cabins.

FIG. 20. Transparent model of submerged test frame for fuselages under combined loading.

FIG. 21. Simple accelerometer and its response curves

FIG. 22. Compound accelerometer and its response curves

FIG. 23. Diagrammatic representation of actual accelerometer.

FIG. 24. Back view of accelerometer with cover plate removed.

FIG. 25. Front view of accelerometer showing counting mechanism.

FIG. 26. Fatigue test on Meteor tailplane representing a wing.

REFERENCES*

* The references are relevant published papers by the author, but it should be noted that much of the work described is as yet unpublished.

[Ref. 1] Research Work in Aircraft Structures (1947), R. & M. of the A.R.C. No. 2327,1951.

[Ref. 2] Records of Major Strength Tests, R. & M. of the A.R.C. No. 2790. (Presented July, 1949; published 1952.)

[Ref. 3] The Principles of Aircraft Strength Testing, The Structural Engineer, November, 1948. (Paper read before Institute of Structural Engineers, November, 1948.)

[Ref. 4] Stability of an Aircraft in a Strength Test Frame, Jour. Roy. Aero. Soc., August, 1947.

[Ref. 5] Destructive Energy in Pressure Cabins, Jour. Roy. Aero. Soc., April, 1950.

[Ref. 6] Fatigue in Aircraft Structures, Jour. Roy. Aero. Soc., August, 1949. (Paper read before the Society in March, 1949.)

DISCUSSIONS OF THE LECTURE

Dr. Karl Arnstein, Vice-President, Goodyear Aircraft Corporation: Before I go ahead with my remarks I should like you to know that, when asked to discuss Dr. Walker's paper, I had good reason to believe that, as is customary, I would be one of a group of discussors. I, therefore, limited my prepared notes to a small section of Dr. Walker's work leaving the bulk of the discussion to my more ambitious colleagues only to find that tonight I am alone on the platform.

Dr. Walker has made an excellent presentation of the manner in which the many complex problems connected with the physicist's approach to aircraft structural research can be solved.

Out of the great wealth of information he has covered, I propose to discuss first the subject of testing of small-scale models, a field in which I have taken particular interest in the past.

The author's emphasis on the importance of careful selection of the elastic characteristics of simplified members in what he calls "Simplified Small-Scale Models" is well placed. Properly designed simplified small-scale models are of great value in the study of the underlying theory of a specific structural problem. One strikingly good example may be found in the model tests made in this country of a main frame of a large rigid airship of the "Hindenburg" class. This frame was composed of girders of approximately equal length located at the periphery of the circular hull section except at the bottom where the frame was built into a deep truss. The frame was braced by radial wires between diametrically opposite corners of the polygon. It was found that certain loads, particularly inwardly acting aerodynamic forces, would cause instability of the frame unless a definite amount of initial wire tension was maintained — an important piece of information that could not easily be gained by the mathematician's approach. On the other hand, I know of efforts where misleading results have been obtained from the use of simplified small-scale models because some elastic characteristics were erroneously considered nonessential and were neglected. The method of analysis with simplified small-scale models is only as good as the simplifying assumptions are, an observation that applies equally well to simplifying assumptions made in a mathematical approach.

Both approaches — through models and mathematics — have been used extensively in the solution of structural problems in the field of rigid airships where exhaustive testing of a full-size airship is not practical.

An example of the development of a mathematical approach can be obtained from a review of the history of the solution for the determination of the distribution of shear and bending stresses in an airship hull. In the early days, three different methods of analysis involving simplifying assumptions were tried: One used the beam theory as a basis; the second used the "method of transverse shears" as a starting point; and the third attempted to consider both, such as the one suggested by Hovgaard in 1922. There were good reasons to believe that the last approximation was the closest. However, it was not until 1938 that an exact solution was developed in the United States by the use of synthesis of type solutions involving difference equations expressed in trigonometric series which proved the reasonable accuracy of the Hovgaard approximation.

It is interesting to note that, prior to the availability of this exact theory, the degree of accuracy of the Hovgaard assumption was completely confirmed by tests on reduced-size true small-scale models, which were scaled down in correct elastic relationship with regard to axial stiffness, radial bending stiffness, and torsional stiffness. With an apology to Dr. Walker, I wish to state that my sympathies still rest very strongly with true small-scale model tests, which model tests I prefer even to measurements on prototype ships. This preference is based on the fact that in testing the prototype ship many strain gages are required at any section of a girder to obtain an accurate picture of the total load in the girder, while, by the use of models, the model members themselves can be designed so that they, in effect, become large strain gages for summing up the stresses imposed on the girders. Another point of interest is that the elastic range of such a model can be made to exceed the scaled-down prototype yield point, and, therefore, stresses may exceed the yield point in some members without damaging the model.

While there are many applications for which models can be used, their use is not recommended in the field of design of joints. It is our practice to test full-scale specimens, for the greatest difficulty in joint design is that some portion of the joint is apt to pick up loads for which it is not designed. Consequently, any simplification of a joint may cause misleading results.

Reviewing the available methods of analysis, we are reminded of the expression "many roads lead to Rome." This is also true for engineers seeking the answer to any one of their many problems. It is my opinion that every engineer should take the road with which he is most familiar and on which he has developed his greatest skill, whether it be the approach by simplified small-scale models, by true complete small-scale models, or by one of the many approaches of mathematics. We are greatly obligated to Dr. Walker for pointing out to us a road not very widely known or used which offers a new and speedy solution to certain problems.

Another remark of Dr. Walker's which interested me was his opinion that "the most efficient designs are most likely to be obtained when the designer deliberately takes a few chances and relies on strength tests to detect any weakness" and that "structures that failed prematurely in the first test were ultimately among the most efficient of them all."

Procedures of this kind were particularly indicated in the early days of aircraft construction, where great care was necessary in order to obtain a sufficiently light structure, since only inefficient materials were available.

When Count Zeppelin submitted his airship design to the Prussian Academy of Science about 60 years ago, he was told that an airship could not lift its own weight if it were to be designed strong enough to withstand any breeze of consequence. The Count succeeded in his work only by taking, not a few, but a great many chances. Consequently, he had a right to believe that the useful lift benefited from the amount of our scientific ignorance and that the useful lift deteriorated with the increased application of scientifically not fully digested information. He considered an airship overweight when it returned from its first trial flight without structural failure.

It is still true today that the greatest advances are made by lessons learned from failure.

In conclusion, I wish to emphasize that Dr. Walker's paper presents some of the important problems confronting the practical designer and gives the status of our knowledge regarding their solutions in an interesting way without the use of obscuring theoretical discussions. The author's beliefs and experience deserve careful study by every practical aircraft designer.

A. B. Callender, Supervisor — Structures Test Laboratory, Glenn L. Martin Company: Dr. Walker's paper is most successful in pointing out basic aspects of aircraft structural testing, this in itself being no mean task with respect to a field of engineering which deals in the main, with problems involving one specially tailored job after another. In addition, he is deserving of a vote of thanks from all of the structural test engineers in the airplane industry for presenting their story so expertly. This important branch of aircraft work merits more publicity than it is usually accorded, among other reasons, because of the competition it faces from newer fields of activity for interest and attention from young engineering graduates.